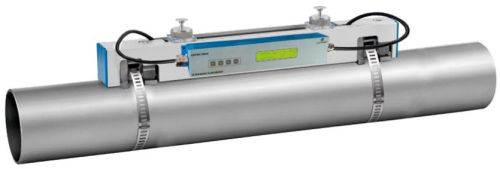

Ultrasonic Flow Meter

Leading Manufacturers, Exporters, Wholesaler, Distributor of Asionic 200 Cf Clamp-On Ultrasonic Flow Meter, Asionic 200 Cfb Clamp-On Ultrasonic Flow Meter, Asionic 200 Ultrasonic Flow Meter, Asionic 200C Clamp On Ultrasonic Flow Meter, Asionic 400 4 Multipath Ultrasonic Flow Meter, Asionic 400 Ultrasonic Flow Meter, Asonic 100 Two Wire Inline Ultrasonic Flow Meter and TS2000-UFM Ultrasonic Flow Meter with Switch from Pune.

| Business Type | Manufacturer, Exporter, Supplier |

| Product PDF | |

| Type | Clamp-On Ultrasonic Flow Meter |

| Media Sensing Method | Differential Transit Type |

| Media Viscosity | 200 CP Maximum |

| Turbidity | Smaller Than 10,000ppm |

| Flow Velocity Range | -12 M/s To +12 M/s (40 Ft/s) |

| Power Supply | 24V DC |

| Accuracy | <+2 %of F.S. + 5mm /sec |

| Line Size | 50NB To 300NB |

| Display | LCD |

| Data Logger | Internal Data Logging |

| Operating Temperature | -40°C To 80°C (Standard), -40°C To 150°C (Optional) |

| Pipe Size | 50 NB (2”) To 300 NB (12”) |

| Electronic Protection Class | IP-67 |

| Sensor Mounting Methods | Field Mount |

Description

ASIONIC™ 200 CF Clamp-On Ultrasonic Flow Meters are designed for accurate flow measurement of liquids in industrial applications. Since the sensors are clamped directly onto the outer surface of the pipe, the system eliminates all process compatibility issues associated with in-line flow meters.

The flow meter operates on Transit Time Measurement Technology, where ultrasonic signals are sent with and against the flow direction. By comparing the travel times, the system accurately calculates fluid velocity and volumetric flow rate. Sonic properties of the pipe and fluid are factored in, ensuring highly repeatable accuracy.

ASIONIC™ 200 CF is ideal for users requiring a non-intrusive, easy-to-install solution that maintains precise flow measurement for clean liquids — especially in applications where:

-

In-line meters were not previously installed,

-

Large pipe diameters exist, or

-

Pipe materials are exotic or incompatible with in-line technologies.

The clamp-on design allows installation without stopping the flow or cutting the pipeline, making it suitable for both retrofits and new process setups.

Features

-

Ultrasonic measurement using Transit Time Technology

-

Easy installation — no need to cut the pipe or stop the flow

-

External transducers require no periodic cleaning

-

No pressure drop or energy loss

-

Bi-directional flow measurement

-

Suitable for a wide range of pipe diameters

-

Portable or fixed installation options

-

Compact and lightweight design

-

Inbuilt data logging

Technical Specifications Performance Characteristics

-

Media: Sonically conductive liquids

-

Sensing Method: Differential transit-time (direct or reflect mode)

-

Viscosity: Up to 200 cP

-

Turbidity: <10,000 ppm with low air bubble content

-

Flow Velocity Range: –12 m/s to +12 m/s (40 ft/s)

-

Accuracy*: ±2% of F.S. + 5 mm/sec

(For velocity range 0.3 m/s to 6 or 12 m/s) -

Line Size:

-

50 NB to 100 NB

-

125 NB to 300 NB

-

For higher line sizes, consult factory

-

-

Acoustic Paths: Single path

-

Display: LCD

-

Communication Interface: RS-485

-

Data Logger: Internal data logging

Electrical Specifications

-

Power Supply: 24V DC

-

Outputs:

-

4–20 mA

-

Pulse (Open Collector)

-

Environmental Conditions

-

Ambient Temperature: –20°C to +60°C

-

Ambient Humidity: 5–95% RH (non-condensing)

-

Operating Temperature – Transducer:

-

Standard: –40°C to +80°C

-

Optional: –40°C to +150°C

-

-

Operating Temperature – Electronics: –10°C to +60°C

Mechanical Specifications

-

Pipe Size Compatibility: 50 NB (2”) to 300 NB (12”)

-

Pipe Wall Thickness: <10 mm

-

Pipe Material Compatibility: MS / SS / Cast Iron / Plastic

-

Sensor Cable:

-

Encapsulated design

-

Standard length: 5 meters

-

-

Sensor Mounting Method: “V” method

-

Transmitter Mounting: Pipe-mounted / wall-mounted

-

Electronic Protection: Field-mount Weatherproof IP-67

Configuration Details

-

Media Type: Sonically conductive liquids

-

Sensor Type: Clamp-on

-

Certification: CE

| Business Type | Manufacturer, Exporter, Supplier |

| Product PDF | |

| Type | Clamp-On Ultrasonic Flow Meter |

| Turbidity | Smaller Than 10,000 Ppm |

| Flow Velocity Range | -12 M/s To +12 M/s |

| Power Supply | Battery Powered 3.6V Rechargeable |

| Accuracy | <+2% Of F.S. + 5mm/sec |

| Line Size | 50NB To 300NB |

| Display | LCD Display |

| Data Logger | Internal Data Logging |

| Ambient Conditions | Temperature -40°C To 80°C, Humidity 5 To 95% Non Condensing |

| Operating Temperature - Transducer | -40°C To 150°C |

| Operating Temperature Pipe Size | -10°C To +60°C |

| Pipe Size | 50 NB To 300 NB |

| Electronic Protection Class | Weather Proof IP-67 |

| Sensor Mounting Methods | Field Mount |

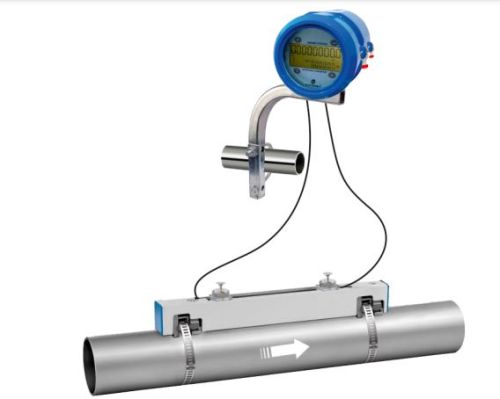

Description

ASIONIC 200 CF-B Battery Powered Clamp-On Ultrasonic Flow Meters are designed for accurate flow measurement of clean, sonically conductive liquids in industrial applications. Since the sensors are clamped externally on the pipe, the system eliminates any risk related to process compatibility commonly associated with in-line flow metering technologies.

The meter operates on the transit time measurement principle, where the instrument calculates fluid velocity by comparing the travel time of an ultrasonic signal moving with the flow versus a signal moving against the flow. By incorporating the sonic characteristics of the fluid and the pipe material, the system delivers highly repeatable and reliable volumetric flow measurements.

ASIONIC 200 CF-B is ideal for applications where easy installation, no process interruption, and zero pipeline modification are required. It is particularly suitable for large line sizes and installations where the use of exotic materials makes in-line metering uneconomical.

Features

-

Ultrasonic measurement using Transit Time Technology

-

Suitable for a wide range of pipe diameters

-

Easy installation — no need to cut the pipe or stop the flow

-

Portable or fixed installation options

-

External transducers require no periodic cleaning

-

Compact and lightweight design

-

No pressure drop or energy loss

-

Inbuilt data logging

-

Bi-directional flow measurement

Technical Specifications Performance Characteristics

-

Media: Sonically Conductive Liquids

-

Sensing Method: Differential Transit Time (Direct or Reflect Mode)

-

Viscosity: Up to 200 cP

-

Turbidity: < 10,000 ppm with low air bubble content

-

Flow Velocity Range: –12 m/s to +12 m/s (40 ft/s)

-

Power Supply: 3.6V Rechargeable Battery

-

Accuracy*: < ±2% of F.S. + 5 mm/sec (for velocity range 0.3 m/s to 6 or 12 m/s)

-

Line Size: 50 NB to 100 NB, 125 NB to 300 NB

-

Acoustic Paths: Single Path

Display & Communication

-

Display: LCD

-

Communication:

-

RS-485 (MODBUS RTU)

-

Pulse (Open Collector)

-

GSM & GPRS

-

-

Data Logger: Internal Data Logging

Ambient & Operating Conditions

-

Ambient Temperature: –20°C to … / Humidity 5–95% (Non-Condensing)

-

Transducer Operating Temperature: –40°C to +80°C (Standard), –40°C to +150°C (Optional)

-

Transmitter Operating Temperature: –10°C to +60°C (14°F to 140°F)

-

Humidity: Up to 99% Relative Humidity (Non-Condensing)

Mechanical Details

-

Pipe Size: 50 NB (2”) to 300 NB (12”), Wall Thickness <10 mm

-

Pipe Material Compatibility: MS / SS / Cast Iron / Plastic

-

Transmitter Mounting: Pipe Mounted / Wall Mounted

-

Electronic Protection Class: Field Mount, Weatherproof IP-67

-

Sensor Cable: Encapsulated Design, Standard Length: 5 m

-

Sensor Mounting Method: “V” Method

| Business Type | Manufacturer, Exporter, Supplier |

| Product PDF | |

| Type | Ultrasonic Flow Meter |

| Power Supply | 90 To 250V AC, 50 Hz / 24V DC (+/-10%) |

| Communication | RS485 MODBUS RTU, GSM, GPRS |

| Output | 4 To 20 MA With HART |

| Response Time | Less Than 1 Sec |

| Process Connections | ANSI 150 Flanged |

| Process Temperature | -20°C To 85°C |

| Process Pressure | 16 Kg/cm² Maximum |

| Data Logging | For 10 Years (Per Day 1 Sample) - Optional |

| Linearity | +0.5% Of MV |

| Temperature Coefficient | +0.05% Per °C |

| Sensor MOC | SS316 |

| Certification | CE Certified |

Description

Electronet series ASIONIC™ 200 is a microcontroller-based, full-bore Ultrasonic Flow Meter designed for accurate measurement of liquid flow in closed pipes. Its rigid and obstruction-less design makes it a maintenance-free alternative to traditional mechanical flow meters.

The system is engineered for dependable performance across diverse industrial environments. User-friendly programming through four front-panel keys provides easy access to extensive diagnostic data. Electronet offers multiple flow meter consoles to meet specific application needs.

Features

-

Ultrasonic measurement using Transit Time Technology

-

EMI/EMC compliant

-

Single / Dual / Quad beam technology for high-precision measurement

-

Excellent long-term stability and reliability

-

Inline and hot-retractable sensor assembly

-

Empty pipe detection

-

No pressure drop

-

Electronic Protection Class:

-

Field-mount Weatherproof IP-67

-

DIN Standard (IP-54)

-

Flameproof (CMRI IIA IIB Certified)

Technical Specifications Performance Characteristics

-

Media: Sonically conductive liquids

-

Line Size: 15 NB to 1000 NB

-

Electronics:

-

Integral (Local)

-

Remote

-

-

Viscosity: Up to 200 cP

-

Turbidity: <10,000 ppm (mg/L) with low air bubble content

-

Display: LCD — 6-digit flow rate & 8-digit totalized flow

-

Calibration Range: Factory calibrated as required

-

Acoustic Paths: Single, Dual & Four Path

Additional Performance

-

Linearity: ±0.5% of M.V.

-

Repeatability: ±0.2% of M.V.

-

Temperature Coefficient: ±0.05% per °C

-

Response Time: <1 sec

Process Conditions

-

Process Temperature: –20°C to 85°C

-

Process Pressure: Up to 16 kg/cm²

-

Process Connections: ANSI 150 flanged (as per table B 16.5)

-

Sensor Pair: As per requirement

-

Sensor MOC: SS316

Material of Construction

-

Flow Tube: SS304 / SS316 / PVC / MS

Electrical Specifications

-

Power Supply:

-

90–250V AC, 50 Hz

-

24V DC (±10%)

-

-

Communication Output:

-

RS-485 (MODBUS RTU)

-

GSM / GPRS

-

-

Output:

-

4–20 mA

-

4–20 mA with HART (Generic)

-

Environmental Conditions

-

Ambient Temperature: –20°C to 75°C

-

Humidity: 5–95% RH (non-condensing)

-

Electronic Protection:

-

Field-mount Weatherproof IP-67

-

DIN Standard IP-54

-

Flameproof (CMRI IIA IIB Certified)

-

-

Certification: CE

| Business Type | Manufacturer, Exporter, Supplier |

| Product PDF | |

| Type | Ultrasonic Flow Meter |

| Measurement Technology | Transit Time |

| Installation | Clamp-On |

| Pipe Line Size | 50 NB To 2000 NB |

| Sensing Method | Differential Transit Type |

| Media | Sonically Conductive Liquids |

| Accuracy | <+2% Of . S. + 5mm /sec |

| Display | LCD |

| Operating Temperature | -20°C To 80°C (Standard), -20°C To 150°C (Optional) |

| Pipe Size | 50 Mm To 2000mm |

| Humidity | Up To 99% Relative Humidity |

ASIONIC™ 200C Clamp-On Ultrasonic Flow Meters accurately measure liquid flow rates in industrial applications without any pipe cutting or process interruption. Since sensors are clamped externally onto the pipe, the system eliminates contamination, pressure drop, maintenance issues, and material compatibility concerns associated with inline flow meters.

The meter uses Transit Time Technology, comparing the travel time of ultrasonic signals moving with and against the flow. This enables accurate and repeatable measurement of fluid velocity and volumetric flow rate while accounting for sonic properties of the pipe and fluid.

ASIONIC™ 200C supports one or two transducer inputs, allowing comparison between two flow streams. It is ideal for applications requiring non-intrusive installation, measurement on large-diameter pipes, or pipelines made from special materials where inline meters are impractical.

Features

-

Ultrasonic measurement using Transit Time Technology

-

Easy installation — no need to cut pipe or stop flow

-

External transducers require no periodic cleaning

-

No pressure drop or energy loss

-

Bi-directional flow measurement

-

Suitable for a wide range of pipe diameters

-

Portable or fixed installation options

-

Compact and lightweight design

-

Inbuilt data logging

-

Pipe Line Size: 50 NB to 2000 NB

-

Sensing Method: Differential transit-time (direct or reflect mode)

-

Media: Sonically conductive liquids

-

Viscosity: Up to 200 cP

-

Turbidity: <10,000 ppm with low air bubble content

-

Accuracy: ±2% of F.S. + 5 mm/sec (Velocity range: 0.3 m/s to 6 or 12 m/s)

-

Acoustic Paths: Single

-

Display: LCD

-

Power Supply Options:

-

90–250V AC

-

24V DC (±10%)

-

Solar powered 24V DC

-

-

Communication Interface: RS-485 MODBUS RTU

-

Data Logging: Internal, inbuilt

-

Ambient Temperature: –20°C to +75°C

-

Ambient Humidity: 5–95% RH (non-condensing)

-

Operating Temperature:

-

Standard: –20°C to 80°C

-

Optional: –20°C to 150°C

-

-

Pipe Size Compatibility: 50 mm (2") to 2000 mm (80")

-

Pipe Wall Thickness: <20 mm

-

Pipe Material Compatibility: MS / SS / Cast Iron / Plastic

-

Sensor Cable: Encapsulated design

-

Standard length: 9 m

-

Optional: up to 15 m

-

-

Sensor Mounting Methods:

-

“V” method

-

“Z” method

-

-

Sensor Types:

-

Small (50 NB–100 NB)

-

Medium (125 NB–300 NB)

-

Large (350 NB–2000 NB)

-

-

Analog Output: Isolated 4–20 mA, 600 Ω load

-

Communication: RS-485 MODBUS RTU

-

Electronics Enclosure: Cast Aluminium / ABS Plastic / SS316

-

Transmitter Mounting: Wall-mounted

-

Electronic Protection:

-

Field-mount Weatherproof IP-67

-

DIN Standard IP-54

-

-

CE Certified

| Business Type | Manufacturer, Exporter, Supplier |

| Product PDF | |

| Type | Ultrasonic Flow Meter |

| Media | Sonically Conductive Liquids |

| Line Size | 15 NB To 1000 NB |

| Display | LCD Display - 6 Digit For Flow Rate & 8 Digit For Totalised Flow |

| Accuracy | < +0.2% Of M.V. |

| Repeatability | +0.1% Of M.V. |

| Temperature Coefficient | +0.05% Per °C |

| Process Temperature | -20°C To 85°C |

| Process Pressure | 16 Kg/cm2 Maximum |

| Power Supply | 230V AC/ 24V DC (+/-10%) |

| Battery Life | 5 To 10 Years Depending On Sampling Time |

| Response Time | Less Than 10 Sec. |

| Electronic Protection Class | IP-67 |

| Ambient Conditions | Temperature -20 To 70°C / Humidity 5 To 95% Non Condensing |

| Data Logging | For 10 Years (Per Day 1 Sample) |

Electronet Series ASIONIC 400-4 Ultrasonic Flow Meters offer the flexibility to install a highly reliable flow measurement system virtually anywhere without compromising accuracy or performance. These meters are extremely easy to use, simple to install, and require no regular maintenance.

Designed for both industrial and domestic applications, they are ideal for:

-

Municipal and industrial water supply

-

Cooling tower systems

-

Water treatment plants

The integrated LCD display provides clear indication of flow rate and totalized flow, accessible through intuitive key selection.

Features

-

Full-bore ultrasonic flow meter for accurate liquid flow measurement

-

Transit Time sensing technology

-

Four-path chordal design for optimal linearity and repeatability

-

High accuracy: ±0.2% of measured value

-

Empty pipe indication and partial flow measurement

-

Negligible pressure drop

-

Optional pressure & temperature measurement

-

IoT-enabled device for smart monitoring

-

Wet calibration as per ISO 17025:2017

(NABL / ILAC Accredited Calibration Laboratory) -

Suitable for clean conductive and non-conductive liquids

| Business Type | Manufacturer, Exporter, Supplier |

| Product PDF | |

| Type | Ultrasonic Flow Meter |

| Media | Liquids |

| Line Size | 15 NB To 600 NB |

| Electronics Output | 4-20 MA DC, Pulse, Frequency |

| Communication Output | RS 485 (MODBUS RTU), GSM, GPRS & RF |

| Viscosity | 200 CP Maximum |

| Display | LCD Display - 7 Digit For Flow Rate & 8 Digit For Totalised Flow |

| Accuracy | < +0.5% Of M.V. |

| Repeatability | +0.5% Of M.V., +0.2% Of M.V., +0.05% Per °C |

| Temperature Coefficient | -20°C To 85°C Maximum |

| Process Temperature | 85°C Maximum |

| Process Pressure | 16 Kg/cm2 Maximum |

| Ambient Conditions | Temperature -20 To 70°C / Humidity 5 To 95% Non Condensing |

| Data Logging | For 5 Years (Per Day 1 Sample) |

Description

Electronet Series ASIONIC®-400 Ultrasonic Flow Meters provide the flexibility to install a reliable flow measurement system virtually anywhere without compromising accuracy or performance. These flow meters are extremely easy to use, simple to install, and require no regular maintenance.

They are designed for a wide range of industrial and domestic applications, including municipal water systems, industrial water distribution, cooling towers, and water treatment processes.

The LCD display provides a clear indication of flow rate and totalized flow, accessible through key selection. In battery-powered models, the display automatically shuts off after 10 minutes to extend battery life and can be turned on again by pressing the “Enter” key.

Features

-

Ultrasonic measurement using Transit Time Technology

-

Full-bore type construction

-

Local indication through LCD display

-

Simple and cost-effective design

-

Empty pipe indication

-

Automatic Meter Reading (AMR) via GSM, GPRS & RF

-

Electronic Protection:

-

Field Mount Weatherproof IP-67

-

DIN Standard (IP-54)

-

Flameproof (CMRI IIA IIB Certified)

-

-

Leak, burst, and tamper detection

-

No pressure drop

Technical Specifications Performance Characteristics

-

Media: Liquids

-

Line Size: 15 NB to 600 NB

-

Number of Paths: Single

-

Electronics:

-

Integral (Local)

-

Remote

-

-

Output:

-

4–20 mA DC

-

Pulse (Open Collector)

-

Frequency (0 to 1 kHz)

-

-

Communication: RS-485 (MODBUS RTU), GSM, GPRS, RF

-

Viscosity: Up to 200 cP

-

Display: LCD — 7-digit Flow Rate & 8-digit Totalized Flow

-

Calibration Range: Factory Calibrated (as per requirement)

-

Accuracy: < ±0.5% of M.V. + 5 mm/sec (Velocity 0.3 m/s to 6 or 12 m/s)

-

Linearity: ±0.5% of M.V.

-

Repeatability: ±0.2% of M.V.

-

Temperature Coefficient: ±0.05% per °C

Process Conditions

-

Process Temperature: –20°C to 85°C max

-

Process Pressure: 16 kg/cm² max

-

Material of Construction: Flow Tube — SS304, SS316, PVC, MS

Power & Operation

-

Power Supply: 24V DC (±10%), Solar Powered (Optional)

-

Low Battery Indication: Provided

-

Battery Life: 5 to 10 years (depending on sampling/communication interval)

-

Response Time: < 10 seconds

Mechanical & Environmental

-

Electronic Protection:

-

Field Mount IP-67

-

DIN Standard IP-54

-

Flameproof (CMRI IIA IIB Certified)

-

-

Process Connection: ASA 150 Flanged (as per Table B 16.5)

-

Ambient Conditions: –20°C to 70°C / 5–95% RH (Non-Condensing)

-

Data Logging: 5-year capability (1 sample per day)

-

Certification: CE

| Business Type | Manufacturer, Exporter, Supplier |

| Product PDF | |

| Type | Ultrasonic Flow Meter |

| Measurement Technology | Transit Time |

| System | 2 Wire With HART Communication |

| Flow Type | Conductive And Non-Conductive Liquids |

| Material | SS 316 |

| Local Indication | LCD Display |

| Sensor Assembly | Integral And Hot Retractable |

| Line Size | 15 NB To 600 NB With Sensor Spool Piece |

| Output | 4 To 20mA DC/ 4 To 20mA DC With HART |

| Display | LCD Display - 5 Digit For Flow Rate & 8 Digit For Totalised Flow |

| Repeatability | +0.5% Of M.V. +0.2% Of M.V. |

| Temperature Coefficient | +0.05% Per °C |

| Process Pressure | 10 Kg/cm² Maximum |

| Power Supply | 24V DC |

| Ambient Conditions | Temperature -20 To +60°C/ Humidity 5 To 95% Non-Condensing |

Features

-

Ultrasonic measurement using Transit Time technology

-

2-wire system with HART communication

-

Full-bore type design

-

Suitable for conductive and non-conductive liquids

-

Material options available based on process requirements

-

Local LCD display for indication

-

Empty pipe detection

-

Electronic protection: Field-mount Weatherproof IP-67 & Flameproof (CMRI IIA IIB Certified)

-

Maintenance-free operation

-

Options for integral and hot-retractable sensor assembly

Description

Electronet series ASIONIC™ 100 are microcontroller-based, 2-wire, full-bore ultrasonic flow transmitters designed for a wide range of industrial applications. These transmitters accurately measure the flow rate of conductive and non-conductive liquids in closed piping systems.

With a simple and robust construction, the instrument ensures obstruction-less flow measurement and requires no mechanical maintenance, making it a reliable alternative to conventional flowmeters. The use of advanced Transit Time Technology ensures superior accuracy, generating a linear 4–20 mA DC output proportional to volumetric flow.

Technical Specifications General

-

Media: Liquids

-

Line Size: 15 NB to 600 NB (with sensor spool piece)

-

Electronics Version:

-

Integral (Local)

-

Remote

-

-

Viscosity: Up to 200 cp

-

Display: LCD — 5-digit flow rate, 8-digit totalized flow

-

Calibration Range: As per requirement (factory calibrated for standard 2 m/s velocity)

Performance

-

Accuracy: ±0.5% of M.V. + 5 mm/sec

(Velocity range: 0.3 m/s to 6 or 12 m/s) -

Linearity: ±0.5% of M.V.

-

Repeatability: ±0.2% of M.V.

-

Temperature Coefficient: ±0.05% per °C

-

Response Time: <10 seconds

Process Conditions

-

Process Pressure: Up to 10 kg/cm²

-

Process Connections: ANSI 150 flanged (as per table B 16.5)

(Other options available on request) -

Mounting: Inline — Horizontal / Vertical

Material of Construction

-

Flange: MS / CS / SS304 / SS316 / PVC

-

Sensor: SS316

Electrical Specifications

-

Power Supply:

-

24V DC

-

24V DC — Two-wire loop powered

-

-

Power Consumption: <40 mW

-

Output: 4–20 mA / 4–20 mA with HART (Generic)

Environmental Conditions

-

Ambient Temperature: –20°C to +60°C

-

Ambient Humidity: 5–95% RH (non-condensing)

-

Electronic Protection:

-

Field-mount Weatherproof IP-67 (DIN Standard IP-54)

-

Flameproof (CMRI IIA IIB Certified)

-

-

Certification: CE

| Business Type | Manufacturer, Exporter, Supplier |

| Product PDF | |

| Type | Ultrasonic Flow Meter With Switch |

| Media | Liquid |

| Line Size | 15 NB To 300 NB |

| Number Of Paths | Single |

| Electronics | Integral (Local) And Remote |

| Remote Cable Length | 5mtr. |

| Output 1 | 4-20 MA |

| Communication Output | RS-485 MODBUS RTU (Optional) |

| Viscosity | 200 CP Maximum |

| Accuracy | < +0.5% Of M.V. For Velocity Range 0.3 M/s To 6 Or 12 M/s |

| Linearity | +0.5% Of M.V. |

| Repeatability | +0.2% Of M.V. |

| Temperature Coefficient | +0.05% Per °C |

| Process Temperature | 200°C Max |

| Process Pressure | 16 Kg/cm² Max |

| Power Supply | 24V DC |

| Electronic Protection | Weather Proof IP-68 |

| Ambient Temperature | 20°C To 75°C |

| Ambient Humidity | 5 To 95% Non-condensing |

-

Ultrasonic measurement using Transit Time Technology

-

Full-bore construction

-

Empty pipe indication

-

Backlit LCD display

-

Durable SS-316 enclosure for superior corrosion resistance

-

IP-68 protection for reliable operation in harsh and wet environments

-

Measuring Principle: Ultrasonic flow measurement

-

Media: Liquids

-

Line Size: 15 NB to 300 NB

-

Number of Paths: Single

-

Electronics: Integral (Local) / Remote

-

Remote Cable Length: 5 meters

-

Output 1: 4–20 mA

-

Output 2: Pulse – Open Collector (Optional)

-

Alarm / Relay Output: 1 Relay Output (Optional)

-

Communication Output: RS-485 (MODBUS RTU) (Optional)

-

Display: Backlit LCD (6-digit Flow Rate, 8-digit Totalizer)

-

Accuracy: < ±0.5% of M.V. (Velocity range: 0.3 m/s to 6 or 12 m/s)

-

Linearity: ±0.5% of M.V.

-

Repeatability: ±0.2% of M.V.

-

Temperature Coefficient: ±0.05% per °C

-

Process Temperature: Up to 200°C

-

Process Pressure: Up to 16 kg/cm²

-

Process Connections: ASA 150 Flanged (As per table)

-

Flow Tube: SS-316

-

Electronics Enclosure: SS-316

-

Sensor: SS-316 / PVC

-

Power Supply: 24V DC

-

Response Time: 1 second

-

Electrical Connection: M12 Connector

-

Electronic Protection: Weatherproof IP-68

-

Sensor / Flow Tube Protection: Weatherproof IP-68

-

Ambient Temperature: –20°C to 75°C

-

Humidity: 5% to 95% (Non-condensing)